Products

Get a Call back Request

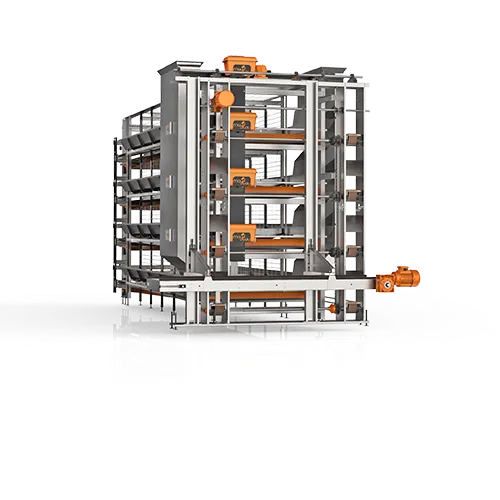

ECO PLUS Chicken Cages

Cage Compartments

The partition wires are designed to allow optimal light and air circulation. The 7º sloped floor wires ensure that eggs easily roll onto the egg collection belt. The back section of the cage compartments is separated using partition wires, ensuring efficient and secure division. The cage doors are horizontally designed for effortless opening and closing. Each compartment measures 60 x 75 cm, with a capacity for 11 chickens. Beneath the egg wires, two 3 mm thick dip-galvanized reinforcement wires provide additional strength and durability.

Watering System

Three stainless steel nipples are installed on “PVC” pipes running the entire length of the cage through the middle of the side panels. Beneath the nipples, a “V” water drainage channel prevents water from reaching the manure belt. Water from the main supply is regulated through a reservoir to maintain appropriate pressure and is distributed via “PVC” pipes. Each tier includes a reservoir. Long-lasting, leak-proof fittings enhance the reliability of the watering system.

Feeding System

The trolley-based feeding system, a preferred method in the poultry industry, ensures feed is distributed evenly and hygienically into the troughs using specialized feed distribution devices. This system prevents spillage, ensures quick and safe feed distribution, and minimizes feed wastage. The feeding system operates fully or semi-automatically using motors with a power range of 0.75 to 1 HP, connected through a rope mechanism. Feed hoppers, made of galvanized sheet metal and assembled with bolts and rivets, deliver feed seamlessly via 127 mm diameter spiral tubes to the feed trolleys. The feeding system is designed to distribute equal portions of properly mixed feed to each tier according to the required gram weight. Freezers at the start of the system are controlled by switches, and control panels and connections are located at the end of the system to manage operations.