Products

Get a Call back Request

Chick Cages

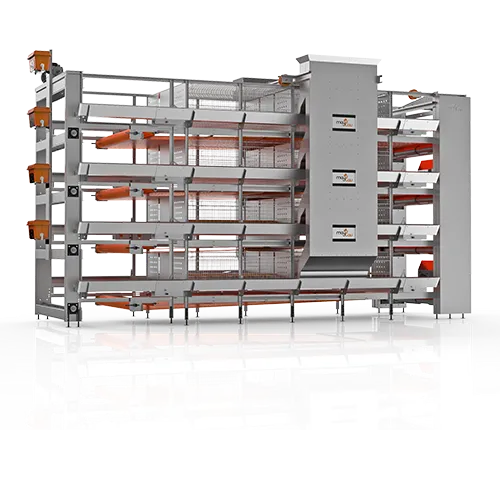

Cage Compartments

The partition wires are designed to allow optimal light and air circulation. The cage floor is covered with 19 x 19 mm galvanized steel mesh, allowing even one-day-old chicks to be placed without the need for additional plastic mesh. The compartments are designed for maximum comfort and efficiency, preventing chicks and pullets from getting stuck or injured. Beneath the floor wires, two 3 mm thick dip-galvanized reinforcement wires enhance the durability of the compartments.

The rear sections of the compartments are divided using partition wires. The cage doors open and close easily in a vertical position. Each compartment measures 65 cm x 120 cm and can accommodate up to 30 chicks.

Watering System

The cage side panels are equipped with 4 stainless steel nipples mounted on “PVC” pipes running along the center of the cage. The drip system attached to the PVC pipe prevents water from reaching the manure belt. Water from the main supply is sent to the “PVC” pipes through a reservoir at the appropriate pressure. Each tier has one reservoir. The watering system uses long-lasting, leak-proof connectors to ensure durability.

Feeding System

Our trolley-based feeding system, preferred in the poultry industry, ensures that feed is evenly and hygienically distributed into the feeding troughs using specialized distribution apparatus. This system prevents spillage, ensures safe and quick distribution, and minimizes feed waste. The mechanism operates either fully or semi-automatically, powered by motors ranging from 0.75 to 1 HP, using a rope system.

Feed hoppers are made of galvanized sheet metal and assembled with bolts and rivets. Feed from silos is distributed flawlessly to the feeding trolleys via spiral augers passing through 127 mm diameter pipes. The feeders are designed to deliver the appropriate amount of feed mixture equally to each tier as required. Control switches at the start of the system and an electric control panel at the endpoint manage the feeding system.

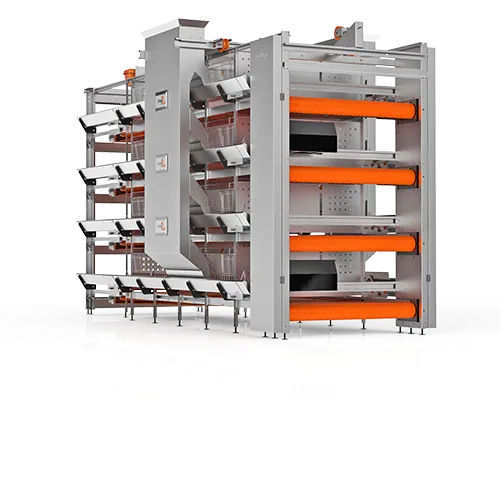

Manure Removal System

Manure is transported using POLYPROPYLENE (plastic) manure belts located under each tier and running along the cage. This process is powered by motors with reducers. Scrapers on each tier ensure that manure is transferred seamlessly to the manure conveyor at the end of the cage. A protective curtain is installed at the rear of the cage to prevent contamination caused by splashes. The rollers at the ends are coated with special rubber for enhanced durability. The control panels used in the manure disposal system are made with premium materials to ensure efficient operation.